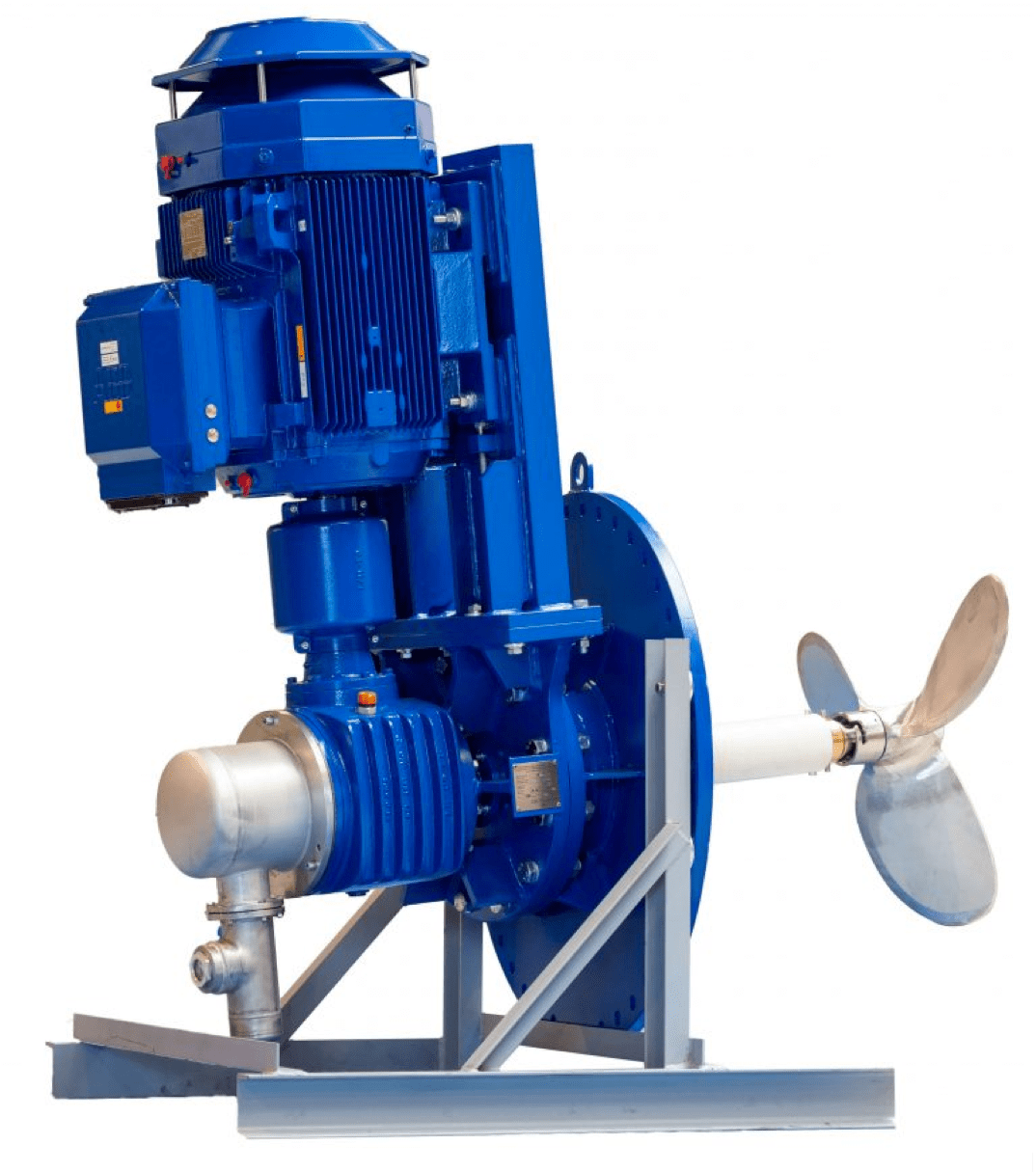

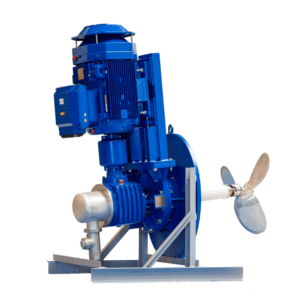

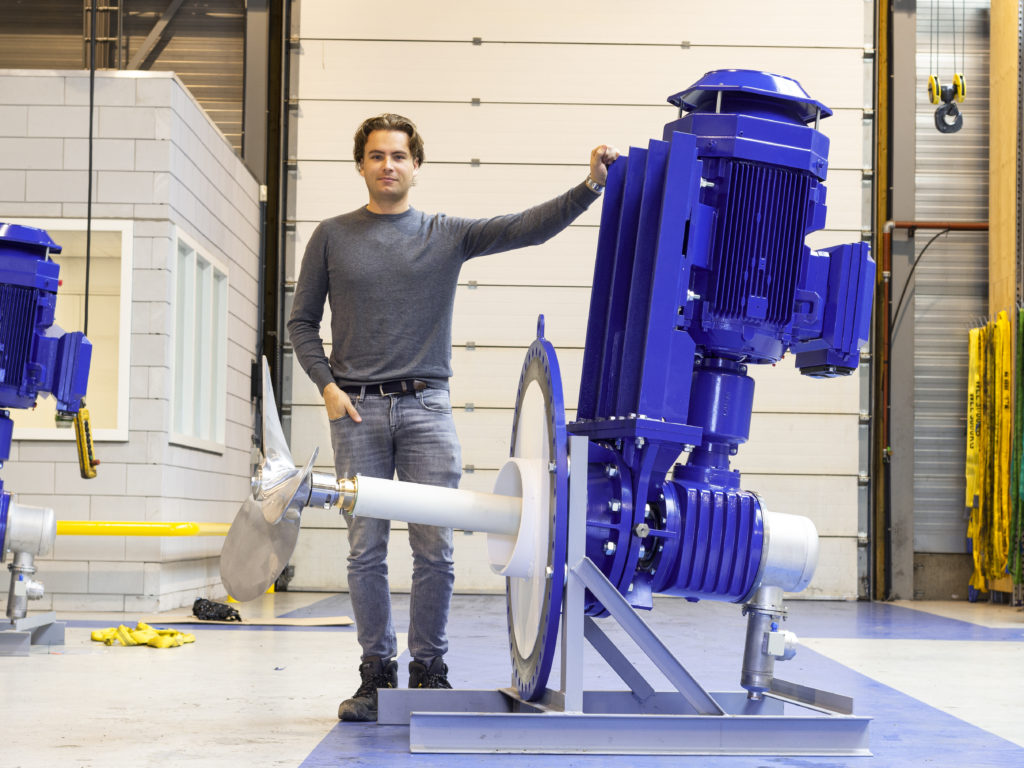

Side-entry tank mixers

Prema-Service tank mixers are efficient, economical and made to last.

Our tank mixers range from side-entry agitators, to static, in-line mixers and extraction columns.

All mixers are also available with ATEX identification EX X II 2G EEx c, k, d T4 according to the explosion protection guideline 2014/34 EC (Zone 1).

What makes us different?

Key components

Compact design

The compact design allows for flange mounting only, where no additional supporting is required.

The gearbox drive minimizes noise and vibrations to ensure a smooth operation.

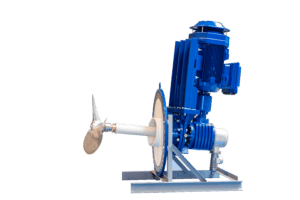

Modular construction

Easy access to interchangable components such as the mechanical seal, the gearbox, the flexible coupling

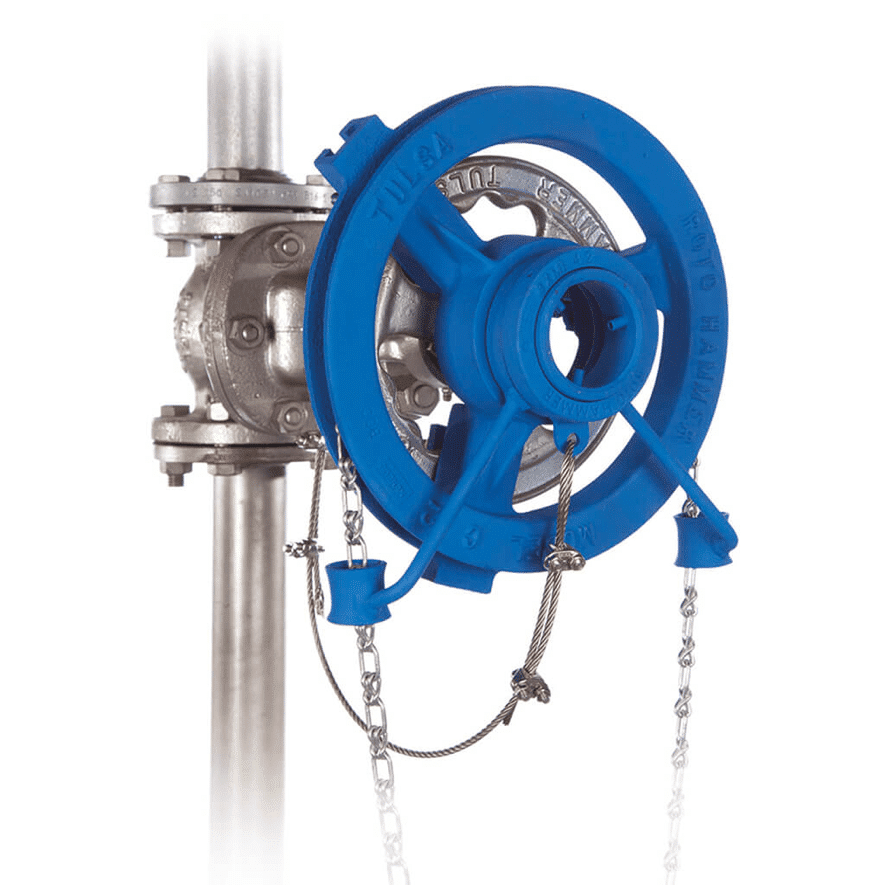

Shut-off device

The shut-off device enables the operator to pull the machine in a locking position.

In this position, the hollow shaft is sealed inside the tank. In this position, the mechanical seal can be changed, the gearbox can be removed, and other maintenance activities can be done while the tank is filled with product.

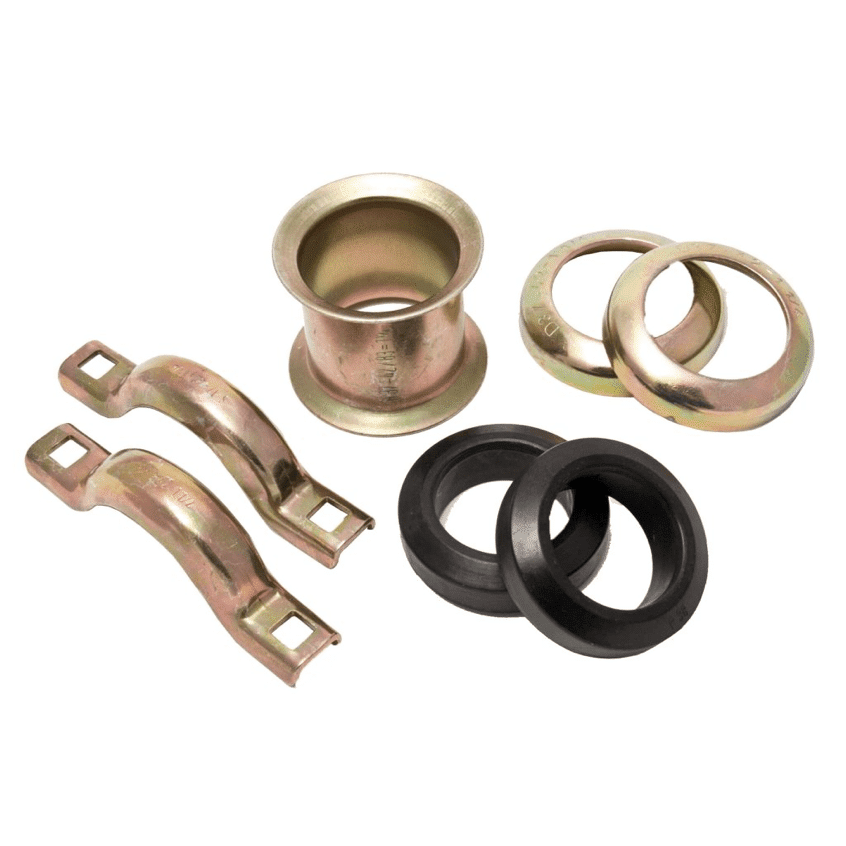

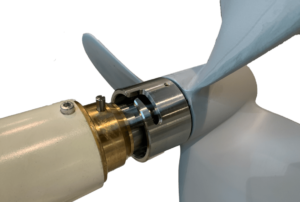

Mechanical seal

The cartridge type mechanical seal is designed for a long life, and excellent performance.

Prema-Service brand mechanical seals are exclusively used in our machines.

Single- and double-acting mechanical seals are available. For the double mechanical seal, a sealing system based on API plan 53/53 is also available.

After training, changing-out a mechanical seal may take less than 1 hour.

High-flow propellor

Our marine-grade welded propellors are custom made for each job. By not using standardized propellors we create maximum efficiency and the highest possible pumping capacity, that results in minimizing the required mixing time.

Depending on the tank size, installed motor power and the desired mixing performance, the propellors are custom built to fit these specifications.

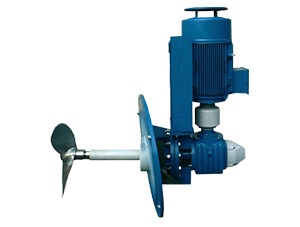

Gearbox

The special design of the gearbox offers unique advantages.

- Undivided shaft

- Quiet running

- Low wear and low maintenance

- Highest safety against overload

Monitoring equipment

Monitoring equipment may be installed as a safety feature, or to monitor the performance of the machines.

Monitoring equipment may include a:

- vibration transmitter,

- leakage detection system,

- pressure monitoring device,

- level sensor

- temperature sensor

Benefits

Compact and robust design

- No need for additional supporting

- Easy access to the mechanical seal

- Seal can be interchanged while the tank is full

- Reduction of noise and vibrations

Portfolio

Tank agitator portfolio

- Fixed type for homogenizing/blending refinery products and chemical products.

- Swivel mixers for the additional prevention of sediment deposits in crude oil or storage tanks and for mixing different storage products. Swivel-type mixers are available in manual-, mechanical or automatic swivel versions.

- Different types of automatic swiveling are available, ranging from simple, continuous swiveling to PLC-controlled swiveling with position detection and program control.

- High-temperature version. This can be used up to 220°C (428°F, 493.15°K), e.g. for bitumen

- Low-noise mixers.

- Double mechanical seal version for all agitators.

- Special sizes and options on request.

Can I help you?

Always happy to help finding the right solution for you!

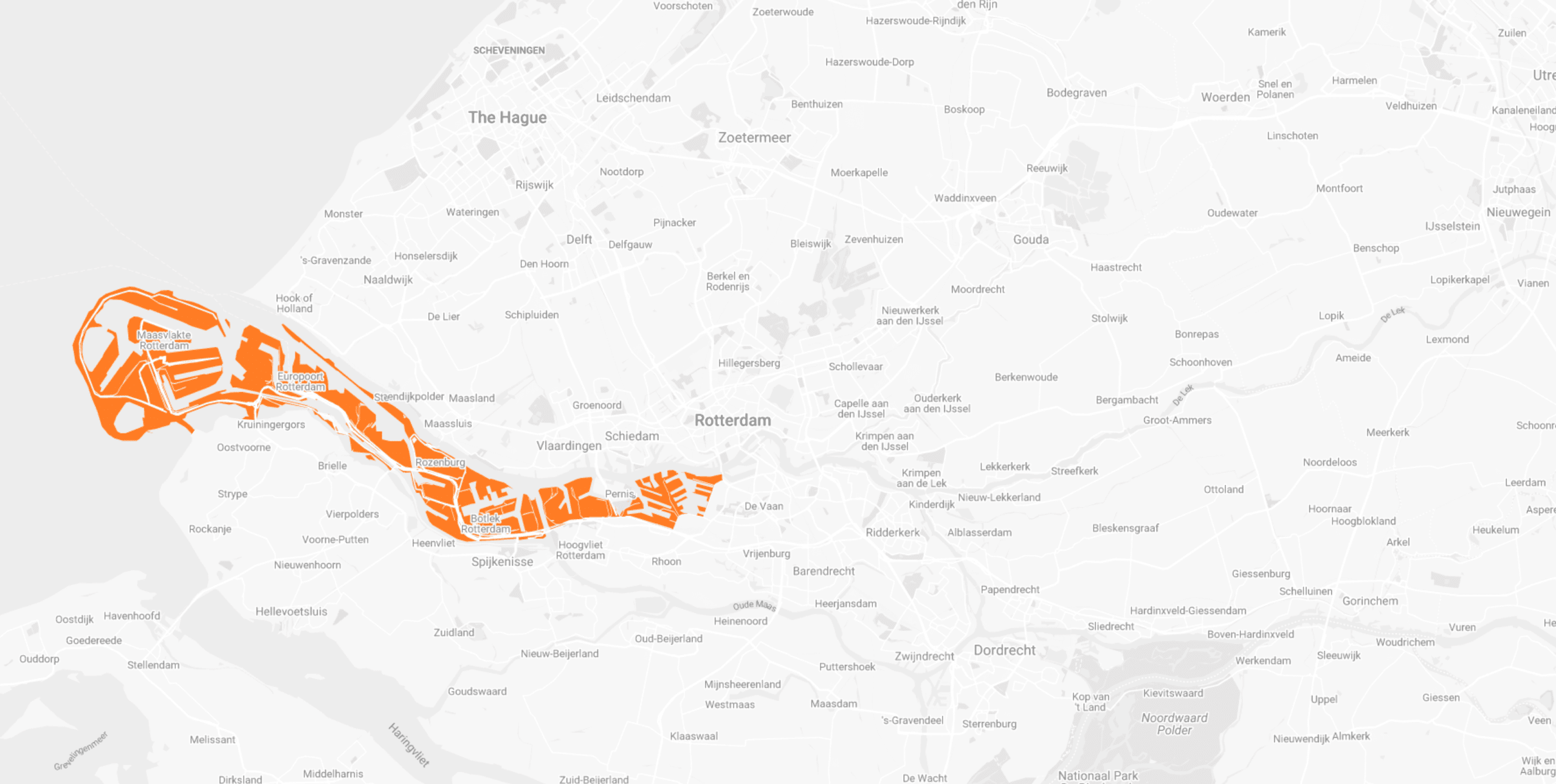

Oranjeberg products

Oranjeberg B.V.

Seggelant-West 5

3237 MJ Vierpolders

The Netherlands